Roughly one-quarter of all freight hauled in the United States is transported in tanker trucks, and of that, nearly half is petroleum products like gasoline, diesel, and aviation fuel.

With so much hazardous cargo on the nation’s roads — and accidents involving cars and road tankers not exactly uncommon — why are there surprisingly few spillages and fatalities?

The credit goes to three things: tanker design, safety equipment, and driver training.

Tanker Design

With roughly 1.22 billion tons of gasoline, Avgas, diesel fuel, Jet A, and other chemicals being hauled each year in tanker trucks that can each hold 10,000 gallons of product, tanker design is vital when preventing accidents.

When hauled, fuel expands and contracts depending on its ambient temperature. It can also move inside the tank and lead to an ever-changing center of gravity for the vehicle.

This potential danger is mitigated by tankers being designed with low centers of gravity, as well as internal bulkheads (or baffles) which separate products and add strength to the tanks (see below).

- Trained Professionals– A semi-trailer will often be transporting 10,000 gallons of fuel and driving the tanker is a highly skilled professional.

- Electronic Stability Control systemscan be fitted to trucks. ESC anticipates rollovers and loss of directional control. It’s an intelligent controller, a box of electronics that can apply brakes on the vehicle in a way that will improve its control. So, for example, if the system perceives that a truck is likely to roll over as it’s going too fast into a corner, ESC can intervene to brake the truck and slow it down.

- Safety Valves– Valves on the bottom of the truck are designed to shear off and safely secure the liquid in the tanker during an accident or if a vehicle drives an undertaker tanker.

- Manlidson the top of the tanker are fitted with roll-over devices that in the event of a rollover will seal the aperture. The danger on the top of the tanker is that the expansion and contraction of the fuel mean that each compartment must be able to breathe (or the pressure in the tank could fracture it catastrophically). Allowing the tank to breathe means that in the event the tanker rolls over, there would be an obvious leak path for liquid to escape which could cause a fire or an environmental catastrophe.

- Internal bulkheads, baffles, and tanks engineered for a low center of gravity– Fuel is expanding and contracting with temperature and moving around the tanker as it drives around corners and is accelerating or braking, which constantly changes the vehicle’s center of gravity. To reduce the impact of this, tankers are designed with very low centers of gravity and have internal bulkheads fitted for strength and to separate each liquid compartment. They also have baffles to reduce product surge when braking or cornering (see below).

- Fires will still occur. The issue is to ensure that in the event of a fire, you design equipment to allow for a uniform burn rather than a catastrophic explosion. A fire will raise the pressure in the tank, but each manlid is fitted with a fire engulfment vent that will release this pressure in a fraction of a second and then re-seal. This will allow the fire to burn but will prevent an explosion.

Baffles in the tank evenly dissipate the force of liquid moving when the truck is accelerating or braking. When braking without baffles, the liquid keeps moving forward to surge and push against the front wall of the tank, dramatically shifting the weight in the tanker and increasing risk of jackknife or rollover. Baffles spread the energy evenly to the entire truck, making the truck easier and safer to handle.

The emphasis on safety-minded design isn’t limited to tankers. It extends to off-loading systems, as well.

When loading or unloading liquids, the liquid moving through the pipes, top loading arms, and bottom loading arms generates static electricity. Because simple static electricity can generate an electrical charge sufficient to ignite vapor from flammable liquids, vapor recovery and grounding is important.

In a closed off-loading system, the vapor is recovered back in the truck containing the flammable vapor and concentrating it, making it too rich to burn.

Because static electricity can build up in the truck when liquid is transferred — or simply from the movement of pipes and truck parts — it’s important that the truck is properly grounded to prevent sparks from igniting any vapor. A grounding system connects the truck to the ground — thus the term “grounding” — and any charge is transferred to the ground, dissipating any built-up electrical charges.

Read more about truck grounding.

It should also be noted that when liquids are transferred at loading areas, it’s not uncommon to have leaks or spills — spills for which operators can incur fines.

With this in mind, the EPA requires truck spill containment protection — like walls and berms — to contain and control leaks and spills.

When loading or unloading tankers, the liquid moving through the pipes, top loading arms, and bottom loading arms generate static electricity. Because simple static electricity can generate an electrical charge sufficient to ignite vapor from flammable liquids, vapor recovery and grounding is important. In a closed off-loading system, the vapor is recovered back in the truck containing the flammable vapor and concentrating it, making it too rich to burn.

Because static electricity can build up in the truck when liquid is transferred or just from the movement of pipes and truck parts, it’s important that the truck is properly grounded to prevent sparks to ignite any vapor. A grounding system connects the truck to the ground (why they call it grounding) and any charge is transferred to the ground dissipating any built-up electrical charges. See more about Truck Grounding

Also, when liquids are transferred, it’s not uncommon to have leaks or spills. The EPA requires truck spill containment protection to contain and control those leaks and spills. Additionally, operators can incur fines for spills.

Foot valves/emergency valves/internal valves have two purposes. They are part of the product transfer mechanism, moving the product into the tanker, and they are designed as a ‘weak or break’ point that sits under the road tankers and are engineered to sheer and close off access to the tanker ensuring minimal or no spillage should the tanker roll, or a car drive under.

API adaptors/tank units, manifolds & dust caps are designed to be robust enough to withstand a collision or rollover incident.

Electronic Stability Control (ESC) systems were initially used in automobiles but in recent years have been applied to the road tanker industry. The system can anticipate a potential rollover incident and will safely apply the road tanker’s brakes to avoid the accident.

With regards to the tanker itself, with around 1.22 billion tons of Gasoline, AvGas, Diesel Fuel, Jet-A, and chemicals being hauled each year in tanker trucks that can hold 10,000 gallons of product each, tanker design is vital when combatting incidents. When hauled, fuel can expand and contract depending on its ambient temperature. It can also move inside the tank and lead to an ever-changing center of gravity for the vehicle. This potential danger is mitigated by tankers being designed to have a low center of gravity. They also have internal bulkheads that separate products and add strength to the tanks.

Technology and equipment within the road tanker industry are continuously improving with the latest incarnation of ‘safe driving’ being the fully automated vehicles. Many professionals within the hazardous cargo industry are concerned that the elimination of any driver’s responsibility could lead to increased, rather than decreased incidents. Tests are currently underway but it’s likely that many years of field trials will be required before the road tanker industry, specifically the segment that transports petroleum products, accepts a driverless vehicle.

SAFETY EQUIPMENT

Over the years, manufacturers have made continuous advancements in tank truck equipment that contributes to the safety of the road tanker and hazardous cargo industries.

Engineered for road tankers by several manufacturers, including Civacon, Emco Wheaton, Girard Equipment, Alpeco, Betts Industries, Dixon Bayco, and Scully — to name just a few — this equipment includes:

- Highly engineered manlids/manholes

- Vapor recovery equipment (valves and vents)

- Foot, emergency, and internal valves

- American Petroleum Industry (API) adaptors/tank units

- Manifolds and dust caps

- Electronic stability control (ESC) systems

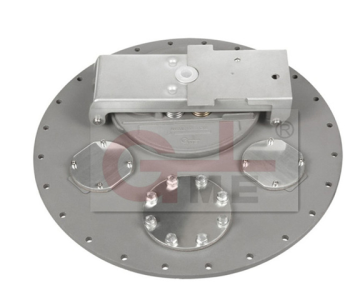

MANLIDS/MANHOLES

Manlids on the top of the tanker are fitted with roll-over devices that will seal the aperture in the event of a rollover.

The danger on the top of the tanker is that the expansion and contraction of the fuel means that each compartment must be able to breathe, or the pressure in the tank could fracture it catastrophically. In the event the tanker rolls over, there would be an obvious leak path for liquid to escape, which could cause a fire or an environmental catastrophe.

While fires will still occur, the goal is to ensure that the equipment is designed to allow for a uniform burn rather than a catastrophic explosion. A fire will raise the pressure in the tank, but each manlid is fitted with a fire engulfment vent that will release this pressure in a fraction of a second and then re-seal. This will allow the fire to burn, but will prevent an explosion.

VAPOR RECOVERY EQUIPMENT (VALVES AND VENTS)

These valves and vents are designed to channel vapors to the correct location rather than cause build-ups in road tankers or vent into the atmosphere.

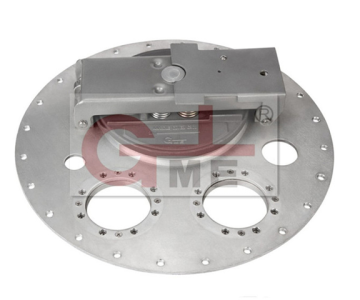

FOOT, EMERGENCY, AND INTERNAL VALVES

As part of the product transfer mechanism, these valves move product into the tanker. They are also designed as ‘weak or break’ points that sit under road tankers, and which shear off and secure the liquid cargo during a rollover or other accident, or if another vehicle drives underneath the tank.

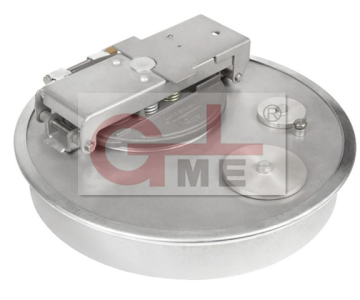

API ADAPTORS/TANK UNITS, MANIFOLDS, AND DUST CAPS

Not only do all of these pieces of equipment ensure safe and reliable fuel delivery, but they are also designed to be robust enough to withstand collisions or rollover incidents.

ESC SYSTEMS

Initially used in automobiles, ESC systems have been applied to the road tanker industry in recent years. These intelligent systems can anticipate a potential rollover incident or loss of directional control, and can safely apply a road tanker’s brakes to prevent an accident.

Note: Although each manufacturer offers slightly different equipment to meet different specifications, the common theme running through all tank truck equipment is that, when fitted to vehicles, it must meet DOT 406 regulations.

A DOT 406 road tanker meets the federal requirements for the transport of gasoline, Avgas, diesel fuel, and Jet A. The equipment allows it to have a maximum operating pressure of 4 psi. It must also meet several other specifications that assist in preventing serious incidents. These include a separate manhole for each compartment, emergency shutoff on the driver’s side front, and rollover protection to prevent manholes from opening on rollover.

If all of the road tanker equipment mentioned above meets DOT 406, it will also assist the tankers in meeting these specifications.

DRIVER TRAINING

A typical semi-trailer will often be transporting 10,000 gallons of fuel. When it comes to hauling such amounts of hazardous cargo, training is key.

While every driver hauling hazardous material is a highly skilled professional, technology and equipment within the road tanker industry are continuously improving with the latest incarnation of so-called ‘safe driving’ being fully automated vehicles.

However, many professionals within the industry are concerned that the elimination of human drivers could result in an increase, not a decrease, in accidents. Tests are currently underway, but it’s likely that many years of field trials will be required before the road tanker industry, specifically the segment that transports petroleum products, accepts driverless vehicles.